Beautiful watch strap!!

Excellent execution once again!

Thank you very much!

I ordered a blue alligator leather strap specially made for my Cartier Santos, including the quick-release system for this model. The strap arrived today and I am absolutely thrilled!

The quality is outstanding — craftsmanship, leather, and fit are all truly top-tier. Visually, the new strap actually suits my watch even better than the original strap.

Big compliments to Artisan Straps — highly recommended!

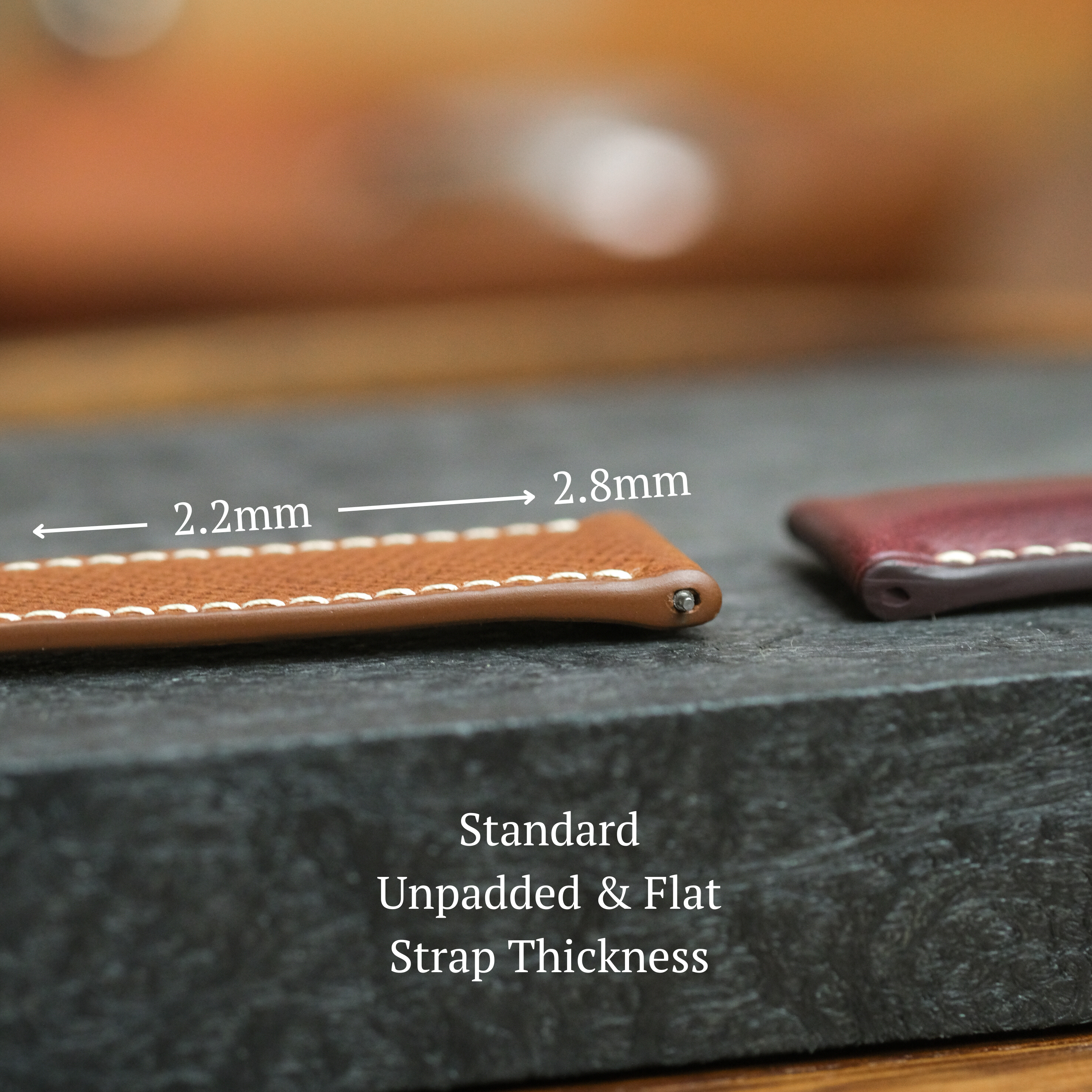

I love my new strap received from Artisan straps.The non padded version felt comfortable from first wear.I live the quality that is first class. I just wish the strap creation was faster since I placed my order on 27/12.Otherwise I would order 3 more right after I received this one.I absolutely adore it....

Very happy with the strap and overall service! Really nicely made and with a feeling of quality.

Thank you.