Good quality and extremely comfortable, with a variety of lengths to choose from to accomodate different wrist sizes.

Fantastic Quality and great customer service. my Panerai looks great with this new strap!

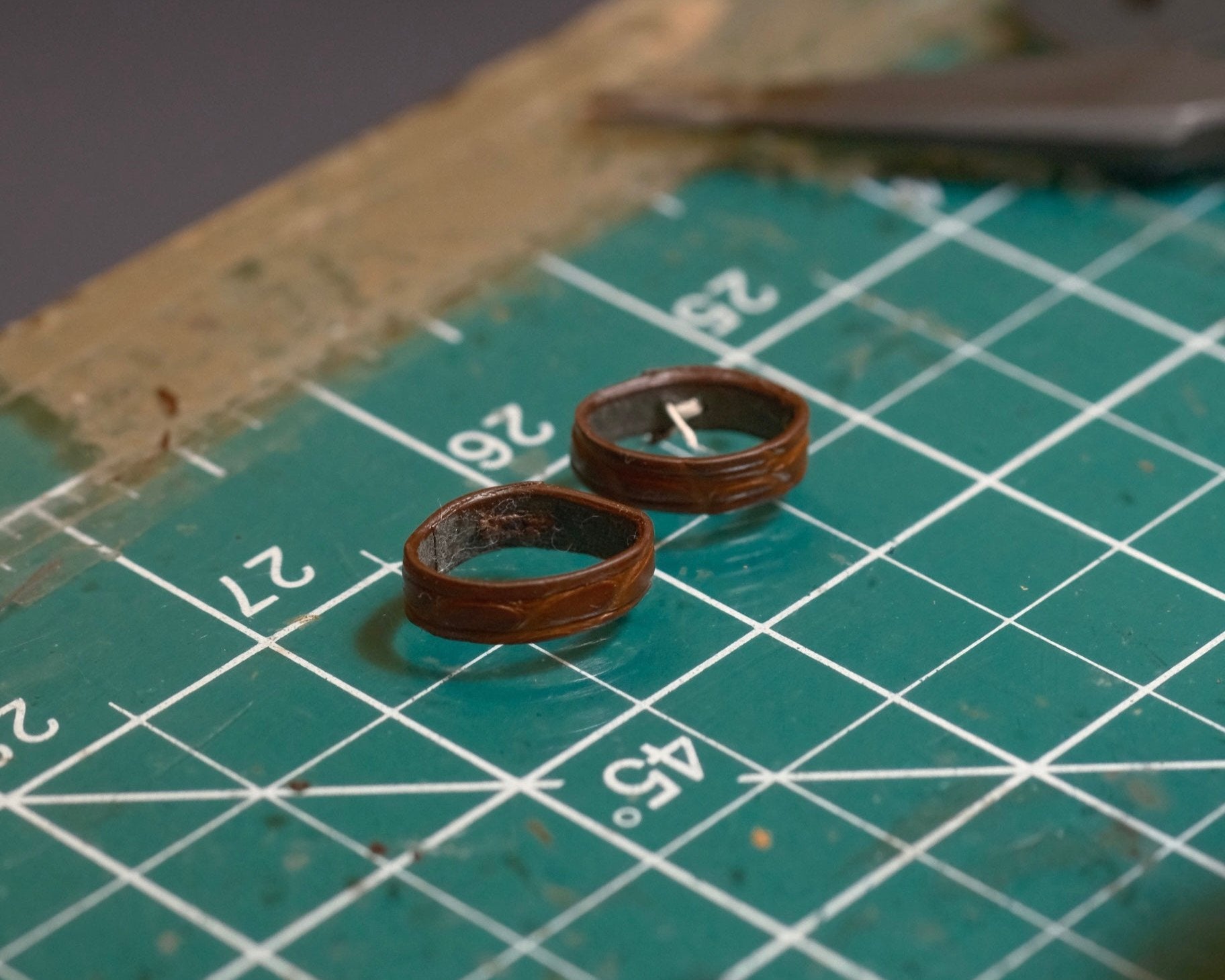

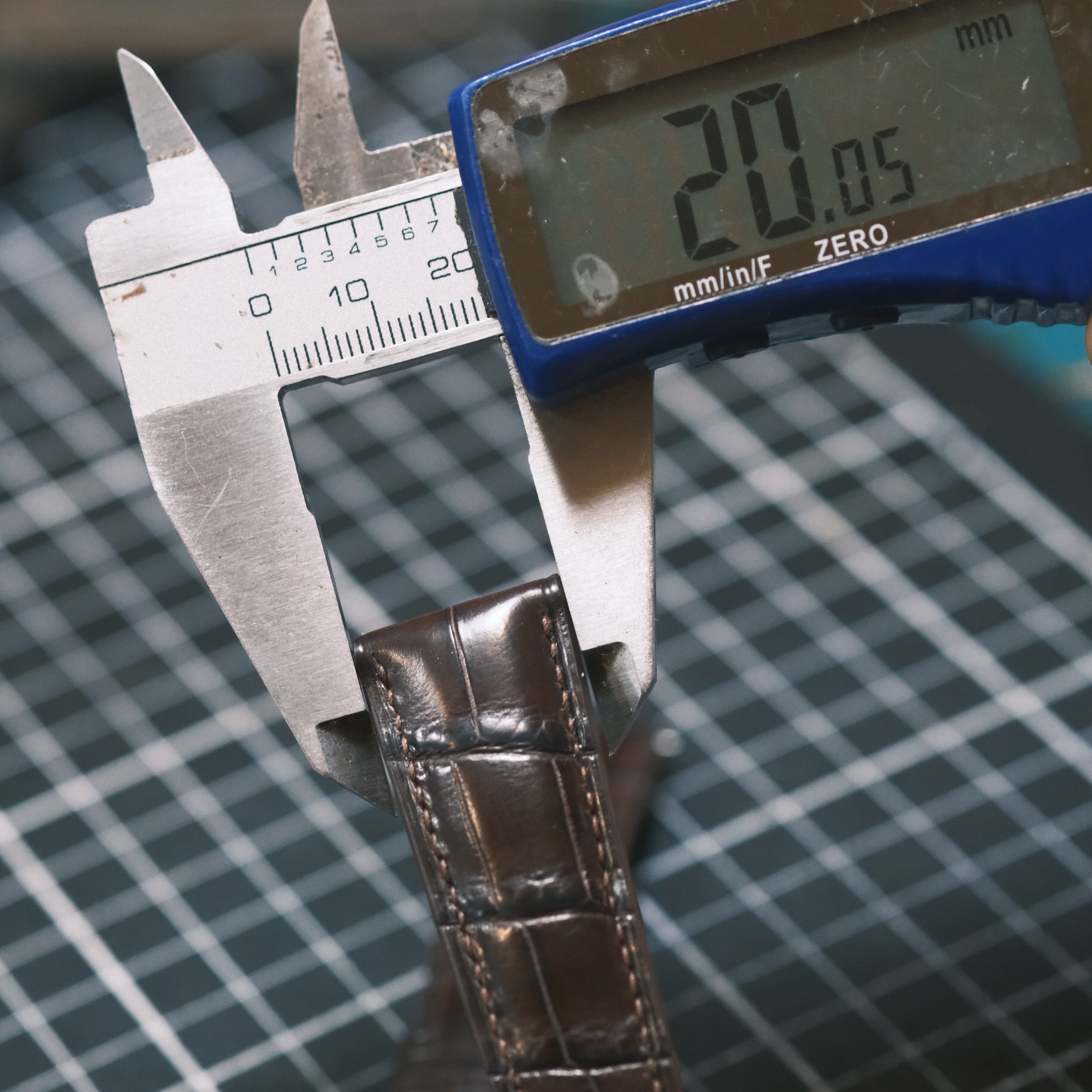

This strap is really well made and is of fantastic quality. I’ve had Artisan Straps make a few straps for me using spring bars so that I can change the strap on this watch to match my outfit. I am very happy with my purchase!

I recently purchased a Dark Brown Alligator Strap, although I haven’t had it fitted to my watch yet the journey so far has been great. Prompt and reliable delivery, the strap was beautifully presented and looks great. Can’t wait to use it. Keep you posted.

Cheers Jeff